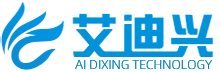

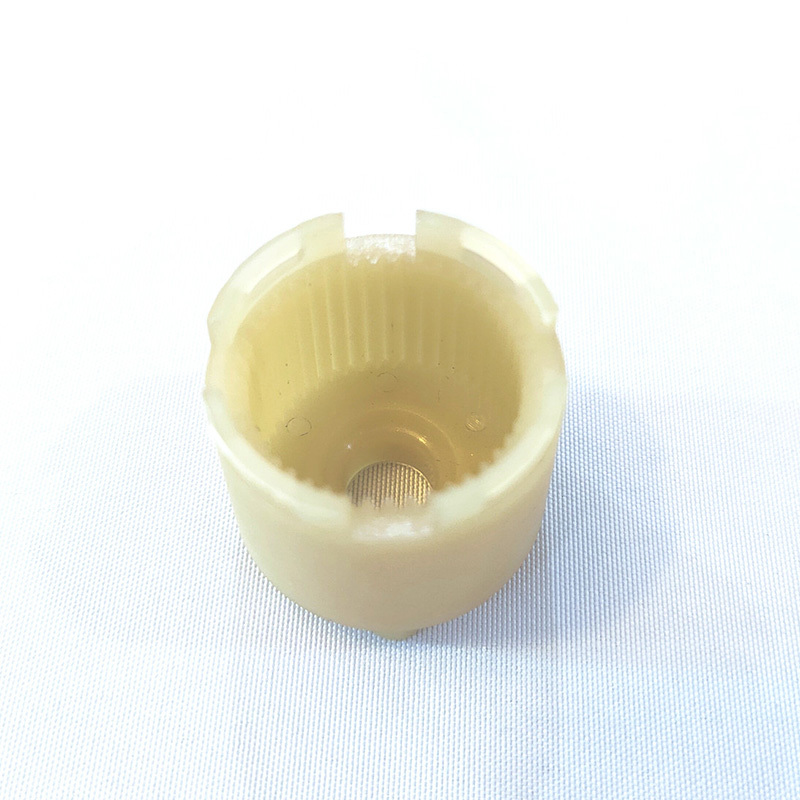

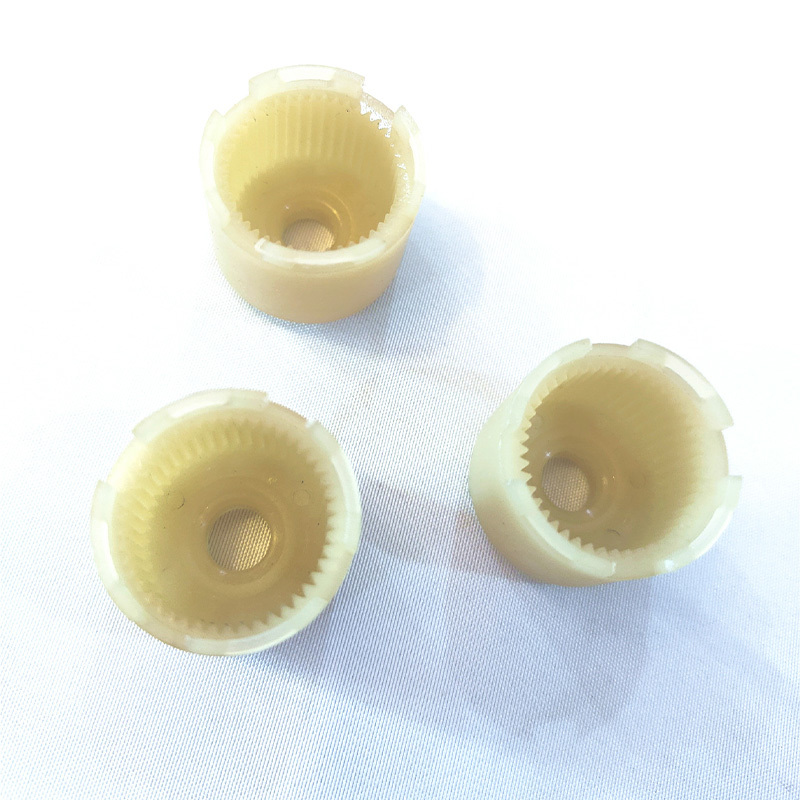

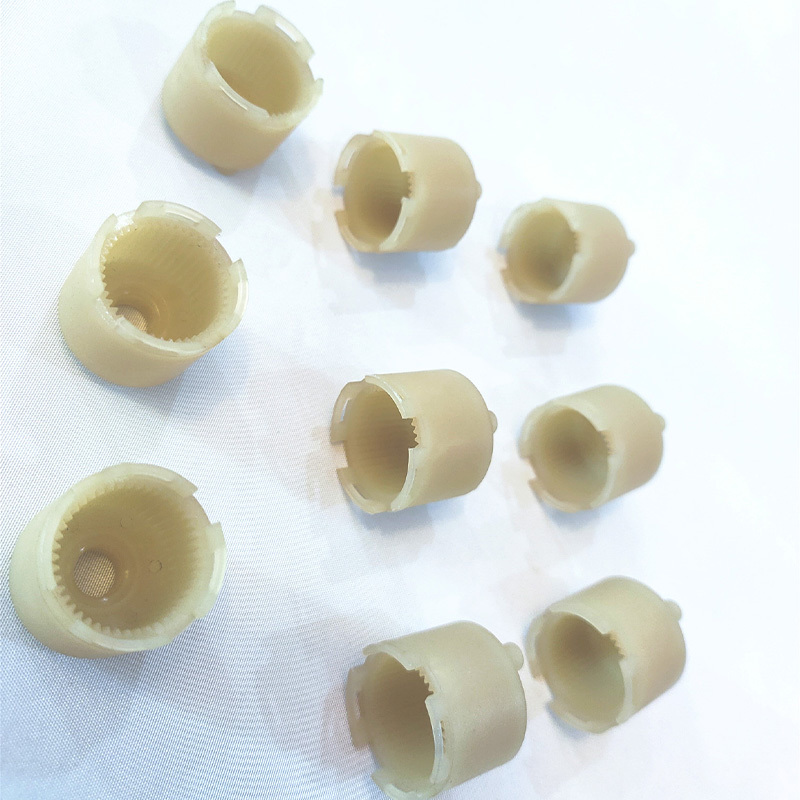

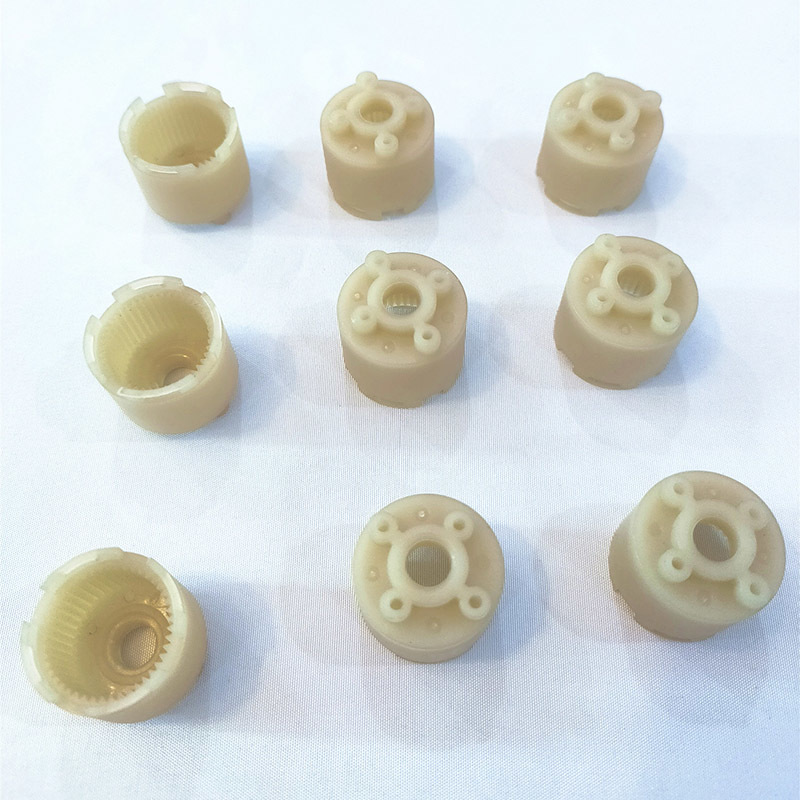

Gear accessories

Key words:

Category:

Product Description

Huizhou Aidixing Intelligent Technology Industrial Co., Ltd.

Passion for ingenuity craftsmanship ● Forging precision gears

Our products are widely used in: automobiles, electric locks, lighting, household appliances, cameras, timers, paper shredders, copiers, optical lenses, robots, cameras, electronic instruments, beauty massage sticks, smoke control, automatic curtains, Attendance machines, vending machines, banknote counters, aircraft models, toys, bathrooms, medical care and other transmission equipment.

We have advanced production equipment and rich production experience, and can customize production according to customer needs.

Our products undergo strict quality testing to ensure that each product meets international standards.

We always uphold the principle of honesty and quality first, and take customer satisfaction as our ultimate goal.

Welcome friends from all walks of life to discuss cooperation!

Let us meet all your needs!

Four advantages tell you why you choose us

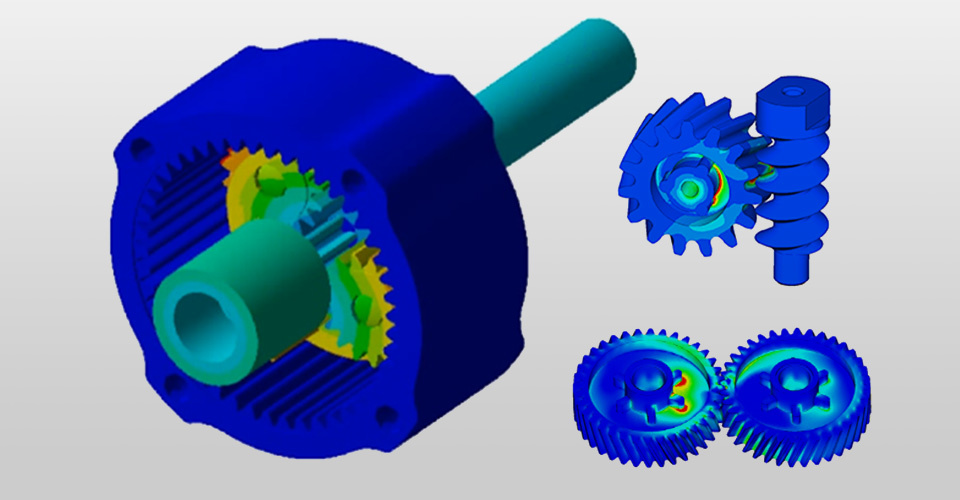

Design Analysis

——

-

Mature gear design analysis software optimizes tooth profile design and improves safety factor and service life.

-

Maintain close communication with customers to understand product functional requirements and precautions, such as parts materials, mechanical strength, dimensional accuracy, surface finish, service life, etc.

-

Strict design review system and checklist check. Before designing, during the design of the plan structure discussion meeting, the designer self-checks according to the checklist; after the design, it is reviewed together with the manufacturing department.

Precision Machining

——

-

Establish an independent processing department to engage in the design and manufacture of Tonggong, to provide peers and customers with high-quality, high-precision products. The roughness of the processed Tonggong can reach Ra0.3, and the accuracy can reach JIS-0.

-

The mold core is mirror-finished by Charmilles C-axis spark machine, the roughness can reach Ra0.3, and the precision can reach 0.001mm.

-

It is produced by a Japanese brand high-precision injection molding machine, with high dimensional accuracy of gears and a small tolerance range, which can be controlled within 0.03mm; the weight deviation is small, and the weight deviation is usually below 0.7%.

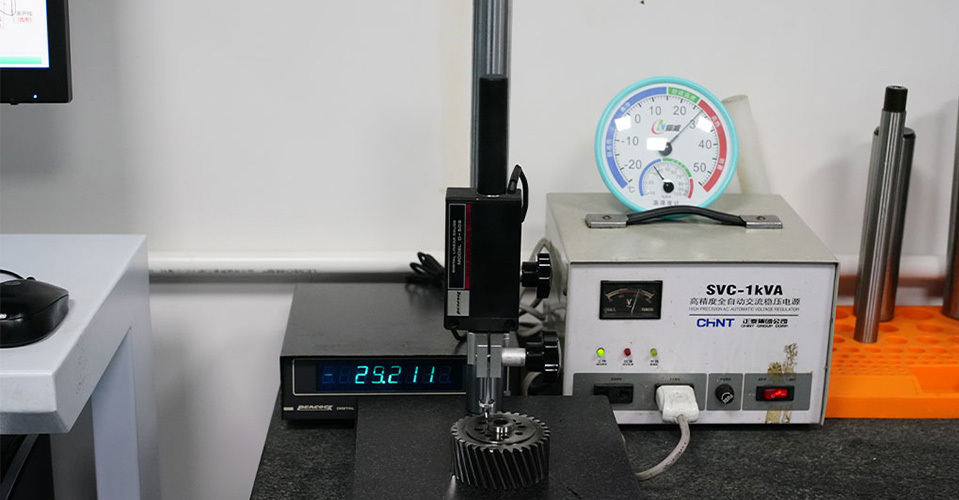

Detail Control

——

-

Sophisticated testing equipment, gear meshing instrument, three-dimensional, roundness instrument, electron microscope and other high-precision testing instruments to ensure product quality.

-

Strictly implement the ISO9001 management system to ensure that all products meet customer requirements.

-

All gear products are fully visually inspected before assembly, and all gearboxes are fully tested before shipment.

Service Customization

——

We formulate different solutions according to the different needs of customers, so as to meet customers' needs for quality, delivery time, and reasonable cost. Warmly welcome your visit and guidance.

Previous page:

Related Products

Project online consultation