Enterprise Advantage

High-precision, low-noise, durable

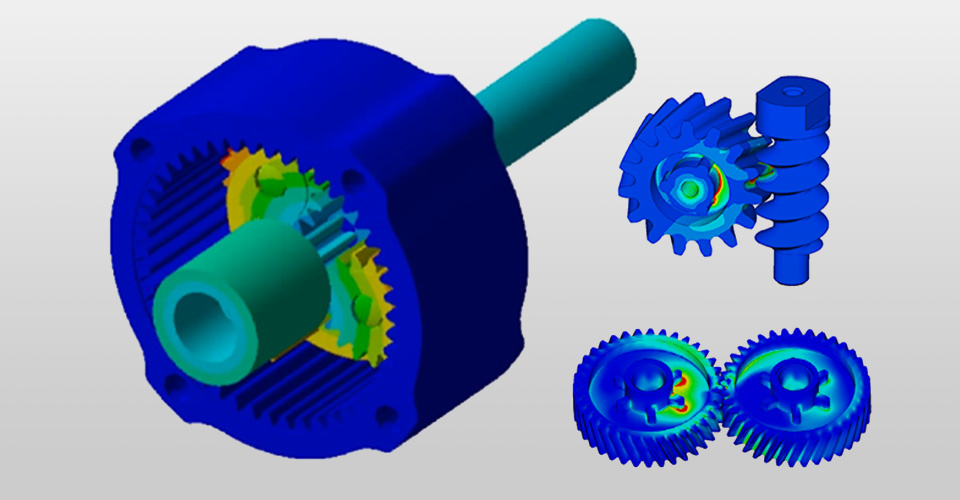

Design Analysis

• Mature gear design analysis software optimizes tooth profile design to improve safety factor and service life.

• Maintain close communication with customers to understand product functional requirements and precautions, such as parts materials, mechanical strength, dimensional accuracy, surface finish, service life, etc.

• Strict design review system and checklist check. Before design, during the design of the plan structure discussion meeting, the designer self-checks according to the checklist; after the design, it is reviewed together with the manufacturing department.

•Established an independent processing department, engaged in the design and manufacture of Tonggong, to provide peers and customers with high-quality, high-precision products. The roughness of the processed Tonggong can reach Ra0.3, and the accuracy can reach JIS-0.

•The mold core is mirror-finished by Charmilles C-axis spark machine, the roughness can reach Ra0.3, and the accuracy can reach 0.001mm.

•It is produced by a Japanese brand high-precision injection molding machine, with high dimensional accuracy of gears and a small tolerance range, which can be controlled within 0.03mm; the weight deviation is small, and the weight deviation is usually below 0.7%.

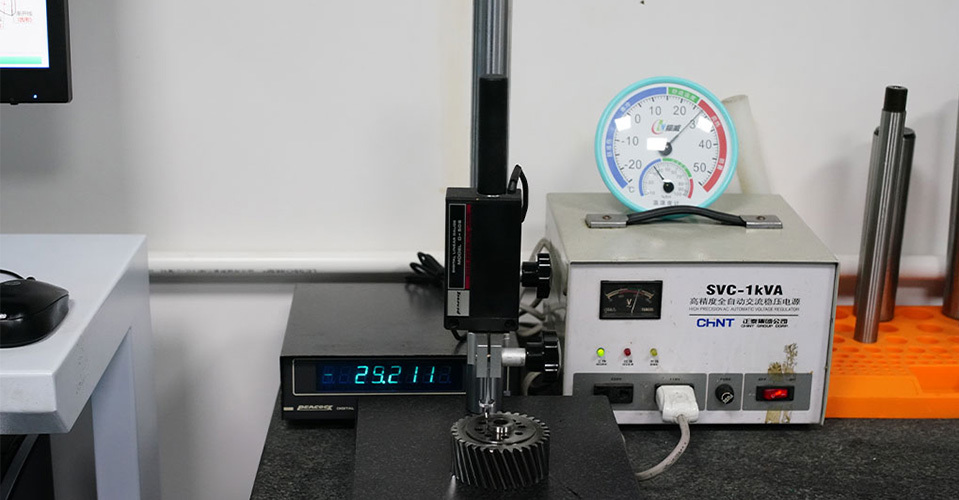

• Sophisticated testing equipment, gear meshing instrument, three-dimensional, roundness instrument, electron microscope and other high-precision testing instruments to ensure product quality.

• Strictly implement the ISO9001 management system to ensure that all products meet customer requirements.

We formulate different solutions according to the different needs of customers, so as to meet customers' needs for quality, delivery time, and reasonable cost. Warmly welcome your visit and guidance.

Scan it

Huizhou Aidixing Intelligent Technology Industrial Co., Ltd.

+86-135 0229 7562(Mr. Gong)

E-mail:sales@gdaidi.cn

Address: 43 Xinglong West 2nd Street, Xiaojinkou, Huizhou, Guangdong

Copyright © Huizhou Aidixing Intelligent Technology Industrial Co., Ltd.